●Isingeniso secala lebhizinisi

Ububanzi bebhizinisi le-transmission technology co., LTD eShanghai buhlanganisa isofthiwe yekhompyutha kanye nehadiwe, izimpahla zehhovisi, ukhuni, ifenisha, izinto zokwakha, izidingo zansuku zonke, ukuthengiswa kwemikhiqizo yamakhemikhali (ngaphandle kwezimpahla eziyingozi), njll.

●Imininingwane yokucubungula

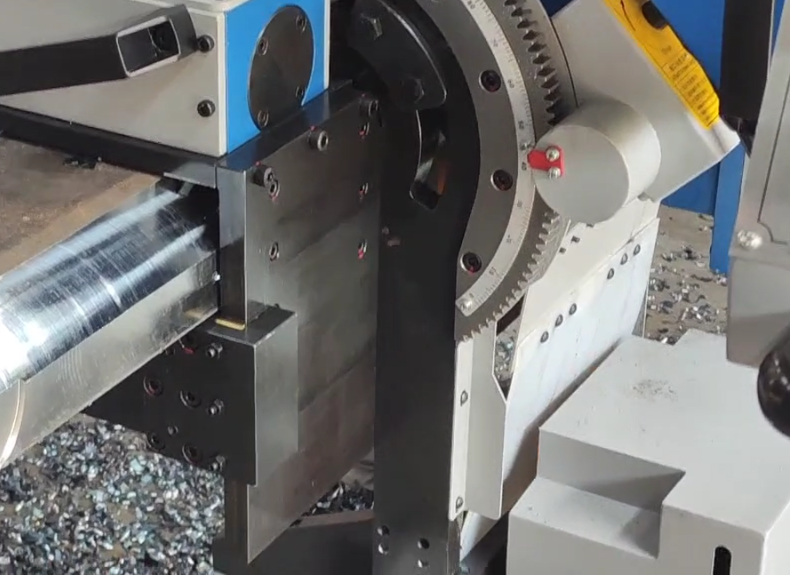

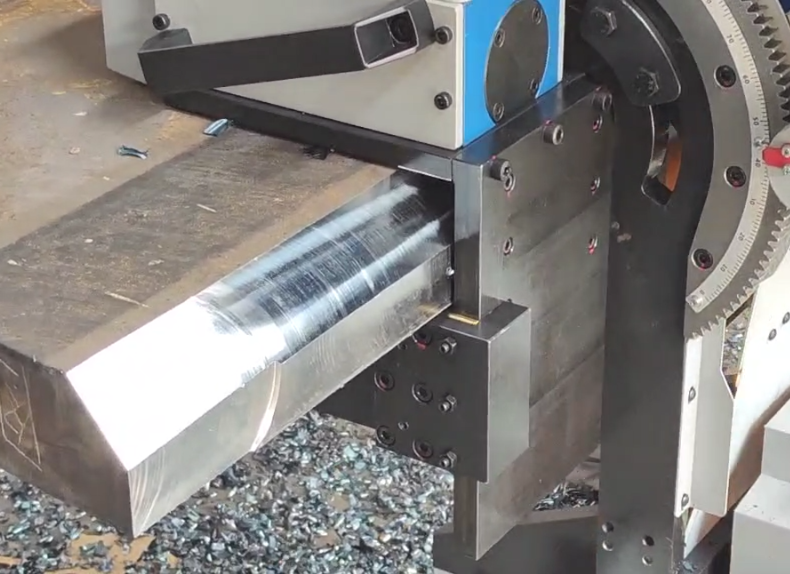

Kuyadingeka ukucubungula inqwaba yepuleti lensimbi eliwugqinsi olungama-80mm. Izidingo zenqubo: umsele ongu-45°, ukujula okungu-57mm.

●Ukuxazulula amacala

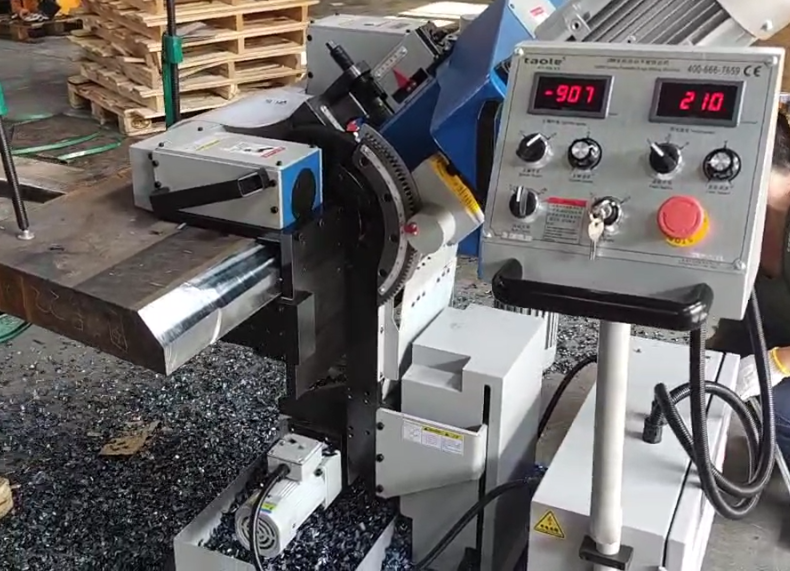

Ngokwezidingo zenqubo yekhasimende, sincoma iTaoleUmshini wokubeka ipuleti esindayo we-GMMA-100Linezinhloko ezimbili zokugaya, ubukhulu bepuleti busukela ku-6 kuya ku-100mm, ingelosi ye-bevel eguquguqukayo kusuka ku-0 kuya ku-90 degrees. I-GMMA-100L ingenza ama-30mm ngokusika ngakunye. Ukusika okungu-3-4 ukuze kufinyelelwe ububanzi be-bevel obuyi-100mm okuyinto esebenza kahle kakhulu futhi esiza kakhulu ekongeni isikhathi nezindleko.

●Isibonisi somphumela wokucubungula:

Ipuleti lensimbi linamathele eshalofini lamathuluzi, futhi uchwepheshe uyalihlola endaweni ukuze afeze ukuqedwa kwenqubo yomsele ngemimese emithathu, kanti ubuso bomsele bubushelelezi kakhulu, futhi bungashintshwa ngqo ngokuzenzakalelayo ngaphandle kokuqhubeka nokugaywa.

Ezweni lokwenziwa kwensimbi, ukunemba nokusebenza kahle kubaluleke kakhulu. Noma yimuphi umkhiqizo owenza lula futhi uthuthukise inqubo uzokwamukelwa ngemfudumalo. Yingakho sijabule ukwethula i-GMM-100L, umshini wokusika ipuleti lokulawula elikude elingenantambo osezingeni eliphezulu. Oklanyelwe ngqo insimbi esindayo, lo mshini oyingqayizivele uqinisekisa ukulungela ukwenziwa okungenamthungo okungakaze kwenzeke ngaphambili.

Khulula amandla e-bevel:

Ukugoba kanye nokugoba kuyizinqubo ezibalulekile ekulungiseleleni amalunga ahlanganisiwe. I-GMM-100L yakhelwe ngqo ukuze iphumelele kulezi zindawo, inezici ezihlaba umxhwele ukuze ivumelane nezinhlobo eziningi zamalunga ahlanganisiwe. Ama-engeli e-bevel asukela ku-0 kuya ku-90 degrees, futhi kungadalwa ama-engeli ahlukene, njenge-V/Y, U/J, noma ngisho nama-degree angu-0 kuya ku-90. Lokhu kuguquguquka kuqinisekisa ukuthi ungenza noma yiliphi ilunga elihlanganisiwe ngokunemba okukhulu kanye nokusebenza kahle.

Ukusebenza Okungenakuqhathaniswa:

Esinye sezici ezivelele ze-GMM-100L yikhono layo lokusebenza ensimbini enobukhulu obungu-8 kuya ku-100 mm. Lokhu kwandisa ububanzi bayo bokusetshenziswa, okwenza ifaneleke kumaphrojekthi ahlukahlukene. Ngaphezu kwalokho, ububanzi bayo obukhulu be-bevel obungu-100 mm bususa inani elikhulu lezinto zokwakha, kunciphisa isidingo sezinqubo ezengeziwe zokusika noma zokushelela.

Thola ukusebenziseka kalula okungenantambo:

Sezidlulile izinsuku zokuboshwa emshinini ngenkathi usebenza. I-GMM-100L iza nesilawuli kude esingenantambo, esikuvumela ukuthi uhambe ngokukhululeka endaweni yakho yokusebenza ngaphandle kokubeka engcupheni ukuphepha noma ukulawula. Lokhu kulula kwesimanje kwandisa umkhiqizo, kuvumela ukuhamba okuguquguqukayo futhi kukuvumela ukuthi usebenzise umshini kuzo zonke izindawo.

Veza ukunemba nokuphepha:

I-GMM-100L ibeka phambili ukunemba nokuphepha. Ifakwe ubuchwepheshe obuthuthukisiwe ukuqinisekisa ukuthi yonke i-bevel cut yenziwa ngokunembile futhi inikeza imiphumela ehambisanayo. Ukwakhiwa okuqinile komshini kuqinisekisa ukuzinza futhi kususa noma yikuphi ukudlidliza okungenzeka kuthinte ukunemba kokusika. I-interface yayo elula ukuyisebenzisa yenza isetshenziswe ochwepheshe abanolwazi kanye nabaqalayo emkhakheni.

Ekuphetheni:

Ngomshini wokusika ishidi lokulawula kude ongenantambo we-GMM-100L, ukulungiswa kokwenziwa kwensimbi kuthathe igxathu elikhulu phambili. Izici zayo ezihlukile, ukuhambisana okubanzi kanye nokulula kokungenantambo kuyihlukanisa nomncintiswano. Kungakhathaliseki ukuthi usebenza ngensimbi esindayo noma amajoyinti ahlanganisiwe ayinkimbinkimbi, lo mshini oyingqayizivele uqinisekisa imiphumela emihle njalo. Yamukela lesi sixazululo esisha futhi ubone ushintsho emisebenzini yokwenziwa kwensimbi.

Isikhathi sokuthunyelwe: Agasti-18-2023