Kev taw qhia txog rooj plaub

Tus neeg siv khoom uas peb tau mus xyuas lub sijhawm no yog ib lub tuam txhab chemical and biological engineering Co., Ltd. Lawv lub lag luam tseem ceeb yog koom nrog kev tshawb fawb thiab kev txhim kho, kev tsim qauv, thiab kev tsim khoom ntawm chemical engineering, biological engineering, H-protection engineering, pressure vessel contracting, thiab engineering equipment. Nws yog ib lub tuam txhab uas muaj peev xwm ua tiav hauv kev tshawb fawb thiab kev txhim kho, kev tsim qauv, kev tsim khoom, kev tsim kho, thiab kev pabcuam.

Cov kev cai ntawm cov txheej txheem ntawm cov neeg siv khoom:

Cov khoom siv ntawm cov khoom ua tiav yog S30408, nrog rau qhov ntev (20.6 * 2968 * 1200mm). Cov kev xav tau ua tiav yog Y-zoo li tus groove, lub V-angle ntawm 45 degrees, V-tob ntawm 19mm, thiab ntug blunt ntawm 1.6mm.

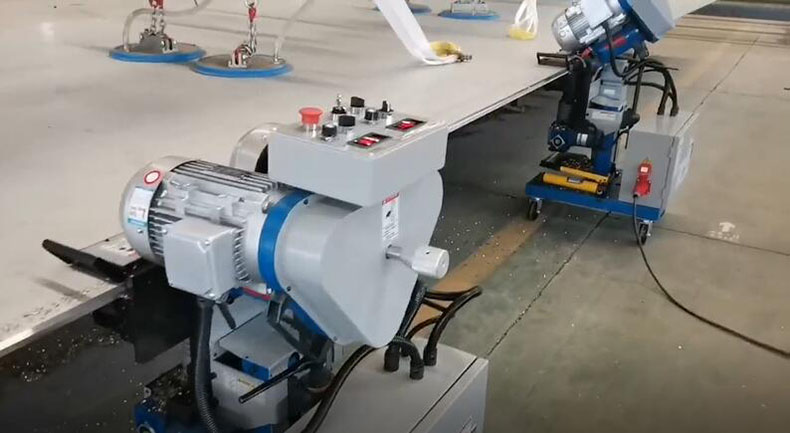

Raws li cov neeg siv khoom xav tau, peb pom zoo kom siv GMMA-80Atshuab beveling hlau phaj:

Yam ntxwv ntawm khoom:

• Tshuab txiav ntug phaj ob chav ceev

• Txo cov nqi siv thiab txo qhov siv zog ua haujlwm

• Kev ua haujlwm txiav txias, tsis muaj oxidation rau ntawm qhov chaw ntawm qhov zawj

• Qhov du ntawm qhov nqes hav ncav cuag Ra3.2-6.3

• Cov khoom no muaj kev ua haujlwm zoo thiab yooj yim siv

Cov khoom tsis

| Qauv Khoom | GMMA-80A | Qhov ntev ntawm lub rooj ua haujlwm | > 300 hli |

| Kev Muab Fais Fab | AC 380V 50HZ | Lub kaum sab xis | 0 ° ~ 60 ° Kho tau |

| Tag nrho lub zog | 4800w | Ib qho dav dav | 15 ~ 20 hli |

| Qhov ceev ntawm lub ntxaiv | 750 ~ 1050r / feeb | Qhov dav ntawm Bevel | 0 ~ 70 hli |

| Kev Ceev Pub Noj | 0 ~ 1500 hli / feeb | Txoj kab uas hla ntawm cov hniav | φ80mm |

| Thickness ntawm clamping phaj | 6 ~ 80 hli | Tus naj npawb ntawm cov hniav | 6 daim |

| Qhov dav ntawm lub phaj clamping | > 80 hli | Qhov siab ntawm lub rooj ua haujlwm | 700 * 760 hli |

| Qhov hnyav tag nrho | 280kg | Qhov loj ntawm pob khoom | 800 * 690 * 1140mm |

Tus qauv siv yog GMMA-80A (tshuab txiav tsis siv neeg), nrog ob lub zog hluav taws xob electromechanical siab thiab hloov kho spindle thiab kev ceev taug kev los ntawm kev hloov pauv zaus ob zaug. Nws tuaj yeem siv rau kev ua cov hlau, hlau chromium, hlau zoo, cov khoom txhuas, tooj liab thiab ntau yam alloys.Feem ntau yog siv rau kev ua haujlwm groove hauv kev lag luam xws li kev tsim kho tshuab, cov qauv hlau, cov hlab ntsha siab, nkoj, aerospace, thiab lwm yam.

Kev xa khoom ntawm qhov chaw ua haujlwm:

Cov nyhuv ntawm kev siv 20.6mm steel phaj nrog ib ntug txiav thiab 45 ° bevel lub kaum sab xis:

Vim yog qhov ntug ntxiv 1-2 hli ntawm lub rooj tsavxwm ntawm qhov chaw, peb lub tuam txhab qhov kev daws teeb meem yog kev sib koom tes ua haujlwm ob lub tshuab, nrog lub tshuab milling thib ob ua raws li tom qab los ntxuav ntug 1-2 hli ntawm lub kaum sab xis ntawm 0 °. Txoj kev no, cov nyhuv groove tuaj yeem ua kom zoo nkauj thiab ua tiav zoo.

Tom qab siv peb covntugtshuab millingrau ib lub sijhawm, cov lus tawm tswv yim ntawm cov neeg siv khoom qhia tau hais tias cov txheej txheem ua cov hlau phaj tau zoo dua qub, thiab qhov nyuaj ntawm kev ua tiav tau txo qis thaum qhov ua tau zoo tau ob npaug. Peb yuav tsum tau yuav nws dua yav tom ntej thiab pom zoo kom peb cov tuam txhab me thiab cov tuam txhab niam txiv siv peb cov GMMA-80Aphaj bevelingtshuabhauv lawv cov chaw ua haujlwm sib xws.

Lub sijhawm tshaj tawm: Lub Rau Hli-30-2025