● Processing specifications

The workpiece of the sector plate, the stainless-steel plate with a thickness of 25mm, the inner sector surface and the outer sector surface need to be processed 45 degrees.

19mm deep, leaving a 6mm blunt edge welded groove underneath.

● Case solving

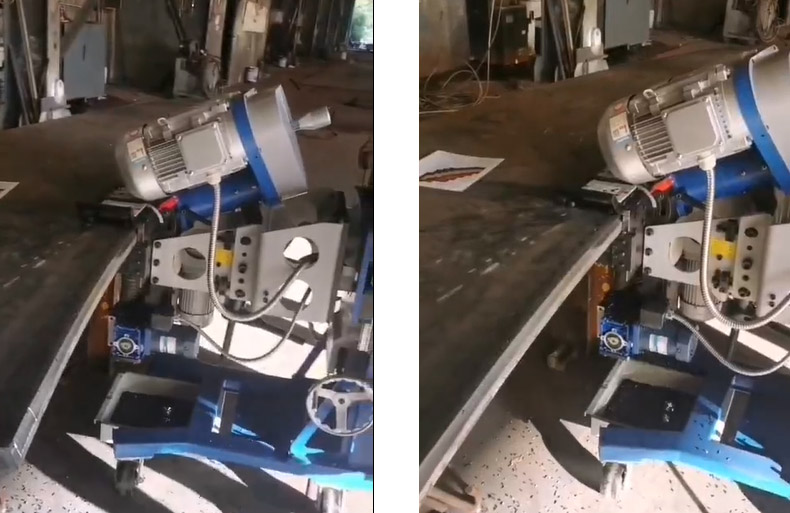

According to the customer's process requirements, we recommend Taole GMMA-80R Turnable steel pate beveling machine for top and bottom bevel with unique design which is turnable for both top and bottom bevel processing. Available for plate thickness 6-80mm, bevel angel 0-60 degree, Max bevel width could reach 70mm. Easy operation with automatic plate clamping system. High efficiency for welding industry, saving time and cost.

●Post-processing effect display:

Introducing the GMMA-80R Turnable Plate Beveling Machine - the ultimate solution for top and bottom beveling. Thanks to its unique design, the machine is able to handle both top and bottom beveling tasks of steel plates.

The GMMA-80R is perfectly engineered to withstand the toughest challenges in the welding industry. This powerful machine is compatible with sheet thicknesses from 6mm to 80mm, making it suitable for a wide variety of applications. Whether you are working with thin or thick plates, the GMMA-80R is effective in achieving precise bevels for your welding projects.

One of the standout features of the GMMA-80R is its impressive 0 to 60 degree bevel angle range. This wide range ensures versatility and enables users to achieve the desired bevel angle according to their specific requirements. In addition, the machine has a maximum bevel width of 70mm for deeper and more thorough bevel cuts.

Operating the GMMA-80R is a breeze thanks to its automatic plate clamping system. This easy-to-use feature ensures a safe and stable hold of the board, minimizing the chance of errors during beveling. With the convenient automatic clamping system, users can save valuable time and effort while maintaining consistent bevel quality.

The GMMA-80R has been designed not only with efficiency in mind, but also with cost-effectiveness in mind. By simplifying the beveling process, the machine significantly reduces welding time and costs, making it an invaluable asset for any welding operation. By increasing efficiency, businesses can increase productivity, meet deadlines, and ultimately generate higher profits.

In conclusion, GMMA-80R Turnable Plate Beveling Machine is the most advanced solution for top and bottom beveling. Its unique design, wide range of bevel angles, and automatic sheet clamping system make it an indispensable tool in the welding industry. Experience the difference and achieve great results with the GMMA-80R.

Post time: Jul-27-2023