● Enterprise case introduction

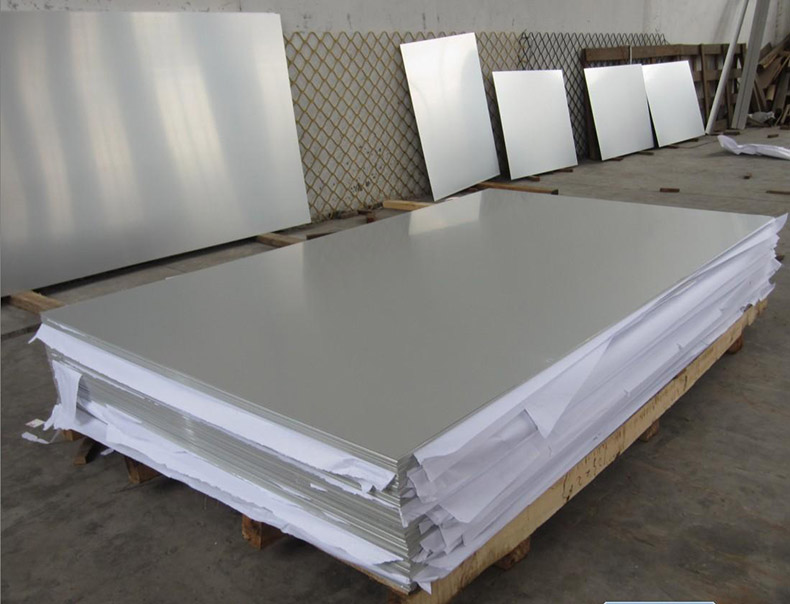

An aluminum processing plant in Hangzhou needs to process a batch of 10mm thick aluminum plates.

● Processing specifications

a batch of 10mm thick aluminum plates.

● Case solving

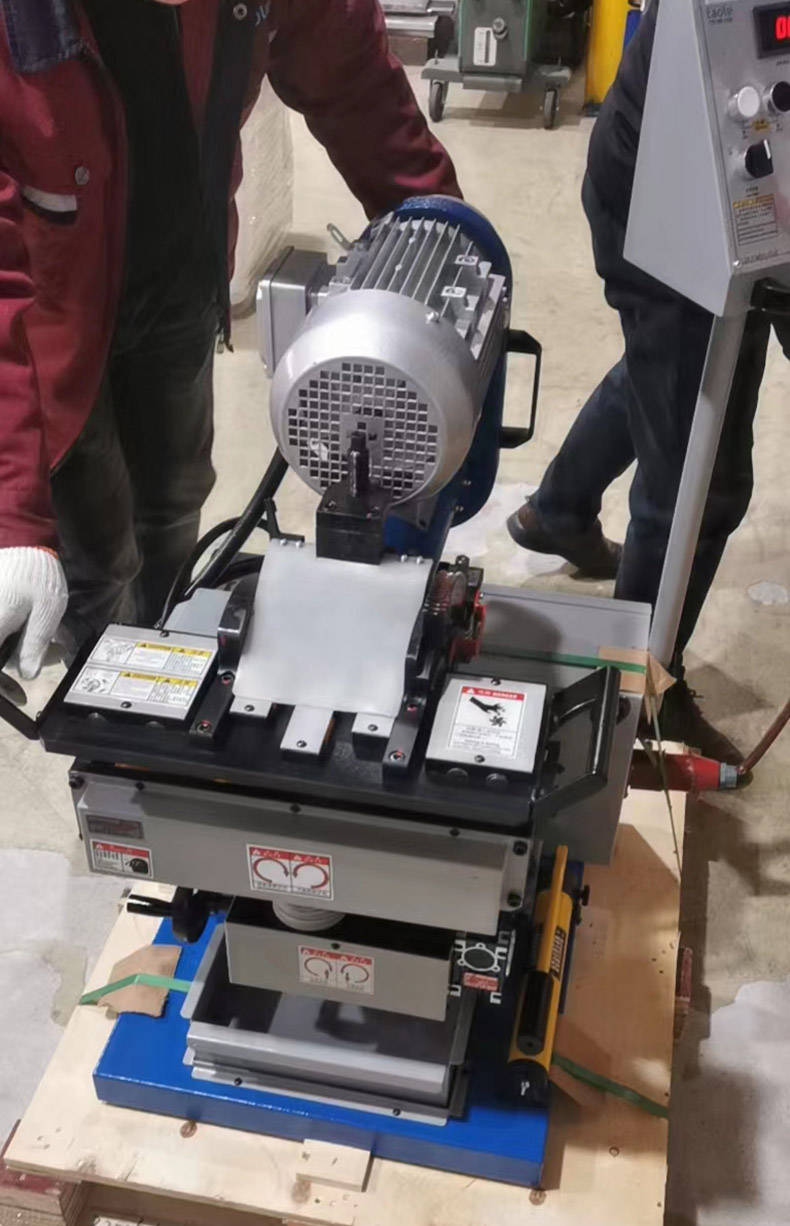

According to the customer's process requirements, we recommend Taole GMMA-60L plate edge milling machine specially for plate edge beveling /milling/chamfering and clad removal for pre-welding. Available for plate thickness 6-60mm, bevel angel 0-90 degree. Max bevel width could reach 60mm. GMMA-60L with unique design available for Vertical milling and 90 degree milling for transition bevel. Spindle adjustable for U/J bevel joint.

●Processing effect display:

After the sample is sent to the customer, the user department analyzes and confirms the processed sample, groove smoothness, angle accuracy, processing speed, etc., and expresses recognition and recognition. The purchase contract was signed!

Introducing the GMMA-60L Plate Edge Milling Machine, a specialized solution for plate edge beveling, milling, chamfering, and clad removal in pre-welding processes. With its advanced features and cutting-edge technology, this machine offers unparalleled precision, efficiency, and versatility.

Designed to streamline welding preparation processes, the GMMA-60L is expertly engineered to perform plate edge beveling with utmost accuracy. The machine's high-speed milling head ensures clean and smooth cuts, eliminating any imperfections that could compromise the quality of the weld joint. This saves time and effort in subsequent welding operations, reducing the need for rework and enhancing overall productivity.

In addition to beveling, the GMMA-60L also excels in chamfering and clad removal. Its flexible milling head and adjustable cutting angles allow for precise chamfering of different materials and thicknesses, ensuring consistent and reliable results. Moreover, the machine's ability to remove clad layers effectively improves the quality and integrity of the weld joint, promoting stronger and more durable connections.

The GMMA-60L Plate Edge Milling Machine boasts a robust construction and exceptional durability, making it suitable for heavy-duty industrial applications. Its user-friendly interface and intuitive controls enable seamless operation, even for operators with minimal experience. The machine is equipped with comprehensive safety features, ensuring the well-being of the operator and minimizing the risk of accidents.

With its outstanding performance, the GMMA-60L is an indispensable tool for fabricators, manufacturers, and welding professionals in various industries such as shipbuilding, construction, and oil and gas. Its ability to efficiently and precisely prepare plate edges for welding enhances the overall quality and aesthetics of the final product.

In conclusion, the GMMA-60L Plate Edge Milling Machine revolutionizes the plate edge beveling, milling, chamfering, and clad removal processes, setting a new standard in precision and efficiency. By investing in this cutting-edge technology, businesses can experience improved welding productivity, reduced rework costs, and enhanced weld joint quality. Upgrade your welding preparation processes with the GMMA-60L and stay ahead in today's competitive manufacturing landscape.

Post time: Sep-01-2023