Short Lead Time for GCM-R3T metal edge rim chamfering machine – Metal Pipe Cutting Machie

Short Description:

Short Lead Time for GCM-R3T metal edge rim chamfering machine – Metal Pipe Cutting Machie Detail:

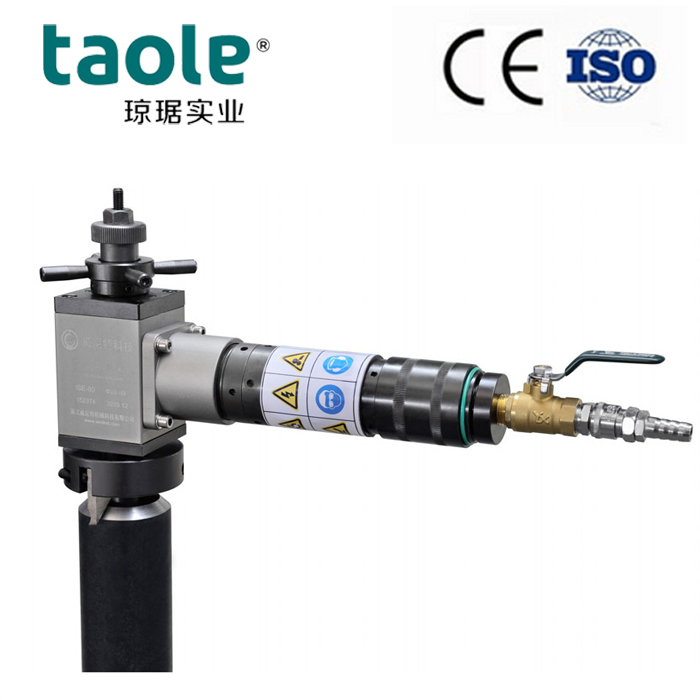

GCM-R3T metal edge rim chamfering machine

Products Introduction

GCM-R3T chamfering machine mainly for edge radiu processing. Available for option R2, R3, C3,C2 as per request. It can process plates in different shape at Clamp thickness 6-40mm for rim chamfering pre-painting.

Specifications

| Model No. | GCM-R3T metal edge rim chamfering machine |

| Power Supply | AC 380V 50HZ |

| Total Power | 790W |

| Spindle Speed | 2800r/min |

| Feed Speed | 0-6000mm/min |

| Clamp Thickness | 6-40mm |

| Process Hole Din | > φ 50mm |

| Process Capacity | R3, R2,C3, C2 |

| Cutter Plate | φ 40mm |

| Cutter QTY | 3 pcs |

| Worktable Height | 775mm |

| Travel Space | 800*900mm |

| Weight | N.W 260KGS G.W 310KGS |

| Packaging Size | 1000*1000*1150mm |

Note: Standard Machine including 1pc cutter head + 2 set of Inserts + Tools in case + Manual Operation

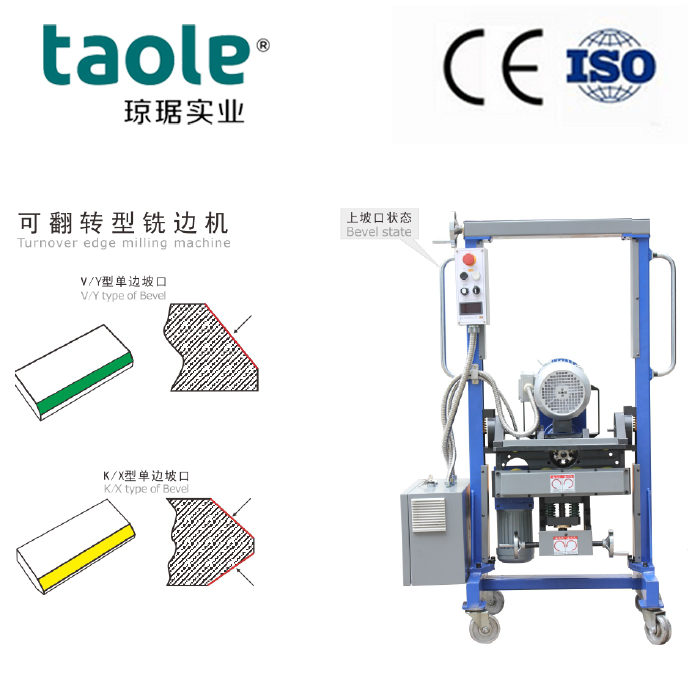

Fetures 1. Available for metal plate Carbon steel,stainless steel, aluminium etc

2. Can process R3,R2,C3,C2 as per customer’s need for metal edge chamfering

3.Cold chamfering, energy saving and Low Noise, More safe and environmental with OL protection

4. Wide working range with Clamp thickness 6-40mm and easy adjustable

5. Easy Operation and high efficiency

Product detail pictures:

Related Product Guide:

All About Die Cutting Machines

Industrial Cutters and Cutting Machines

Every single member from our large efficiency profits team values customers' requirements and organization communication for Short Lead Time for GCM-R3T metal edge rim chamfering machine – Metal Pipe Cutting Machie, The product will supply to all over the world, such as: Nepal, Cape Town, Suriname, What You Need Is What We Pursue.We are sure our products will bring you first class quality.And now sincerely hope to promote partner friendship with you from all over the world. Let's joint hands to cooperate with mutual benefits!

The product classification is very detailed that can be very accurate to meet our demand, a professional wholesaler.