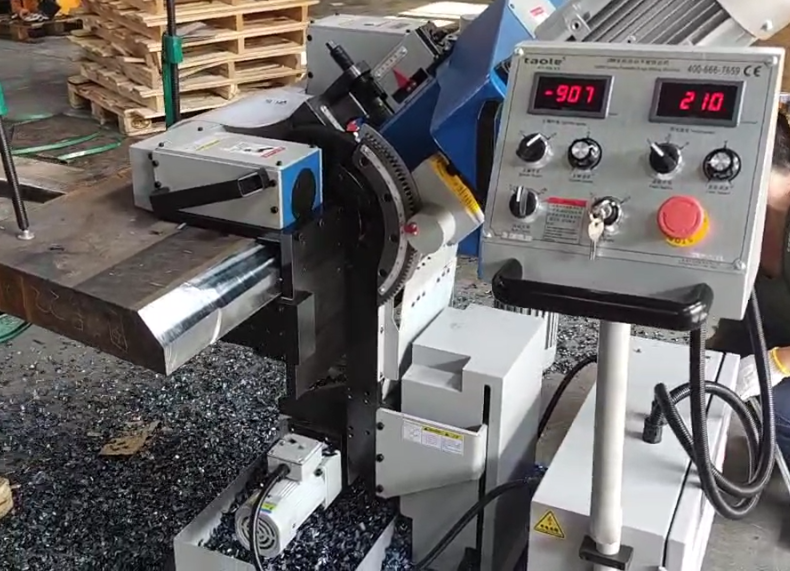

● Enterprise case introduction

The business scope of a transmission technology co., LTD in Shanghai includes computer software and hardware, office supplies, wood, furniture, building materials, daily necessities, chemical products (except dangerous goods) sales, etc.

● Processing specifications

It is necessary to process a batch of 80mm thick steel plate. Process requirements: 45° groove, depth 57mm.

● Case solving

According to the customer's process requirements, we recommend Taole GMMA-100L heavy duty plate beveling machine with 2 milling heads, plate thickness from 6 to 100mm, bevel angel from 0 to 90 degree adjustable. GMMA-100L can make 30mm per cut. 3-4 cuts to achieve bevel width 100mm which is high efficiency and helps a lot for saving time and cost.

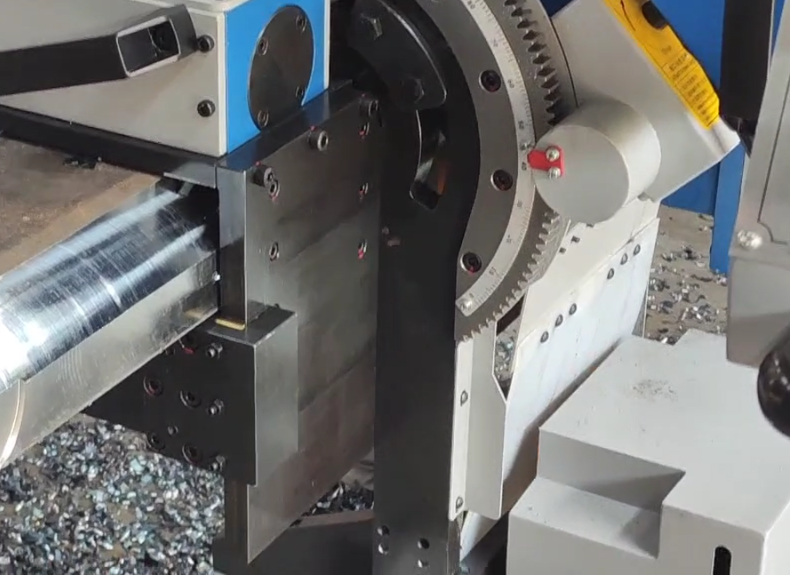

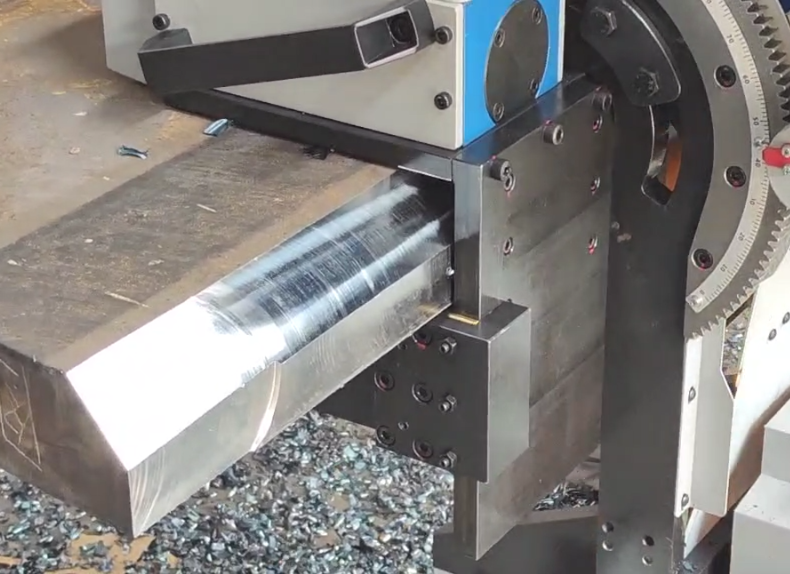

●Processing effect display:

The steel plate is fixed on the tooling shelf, and the technician tests it on site to achieve the completion of the groove process with 3 knives, and the groove surface is also very smooth, and it can be directly welded automatically without further grinding.

In the world of metal fabrication, precision and efficiency are paramount. Any product that simplifies and enhances the process will be warmly welcomed. That's why we are pleased to introduce the GMM-100L, a cutting-edge wireless remote control plate beveling machine. Specifically designed for heavy sheet metal, this exceptional equipment ensures seamless fabrication readiness never before possible.

Unleash the power of the bevel:

Beveling and chamfering are essential processes in the preparation of welded joints. The GMM-100L has been specifically designed to excel in these areas, boasting impressive features to suit a wide variety of weld joint types. Bevel angles range from 0 to 90 degrees, and different angles can be created, such as V/Y, U/J, or even 0 to 90 degrees. This versatility ensures that you can perform any welded joint with the utmost precision and efficiency.

Unparalleled Performance:

One of the outstanding features of the GMM-100L is its ability to operate on sheet metal with a thickness of 8 to 100 mm. This expands its range of application, making it suitable for a variety of projects. In addition, its maximum bevel width of 100 mm removes large amounts of material, reducing the need for additional cutting or smoothing processes.

Experience wireless convenience:

Gone are the days of being chained to a machine while working. The GMM-100L comes with a wireless remote control, allowing you to move freely around your workspace without compromising safety or control. This modern convenience increases productivity, allows for flexible mobility and allows you to operate the machine from every angle.

Reveal precision and safety:

The GMM-100L prioritizes precision and safety. It is equipped with advanced technology to ensure that every bevel cut is performed accurately and provides consistent results. The machine's solid construction ensures stability and eliminates any potential vibrations that could affect cutting accuracy. Its user-friendly interface makes it usable by both seasoned professionals and novices in the field.

in conclusion:

With the GMM-100L wireless remote control sheet beveling machine, metal fabrication preparation has taken a big step forward. Its unique features, wide compatibility and wireless convenience set it apart from the competition. Whether you're working with heavy sheet metal or intricate welded joints, this exceptional piece of equipment guarantees outstanding results every time. Embrace this innovative solution and witness a revolution in metal fabrication workflows.

Post time: Aug-18-2023