The switchboard industry plays a vital role in ensuring that electricity is distributed efficiently and safely. Small sheet metal beveling machines are one of the key components in the manufacturing process of these cabinets. These machines are designed to create precise bevels on the edges of sheet metal, which is essential for a variety of applications in switchboard assembly. The use of small sheet metal beveling machines in this industry improves the overall quality and durability of cabinets. By beveling the edges of metal sheets, manufacturers can ensure a better fit and alignment during assembly. This precision reduces the risk of gaps and misalignments, thereby avoiding potential electrical hazards. In addition, the beveled design facilitates better welding and joining processes, resulting in a stronger, more reliable connection.

The client we are serving this time is a company in Cangzhou, mainly engaged in the manufacturing and processing of chassis, cabinets, distribution cabinets and accessories, involving mechanical processing, production of environmental protection equipment, dust removal equipment, oil fume purification equipment and environmental protection equipment accessories.

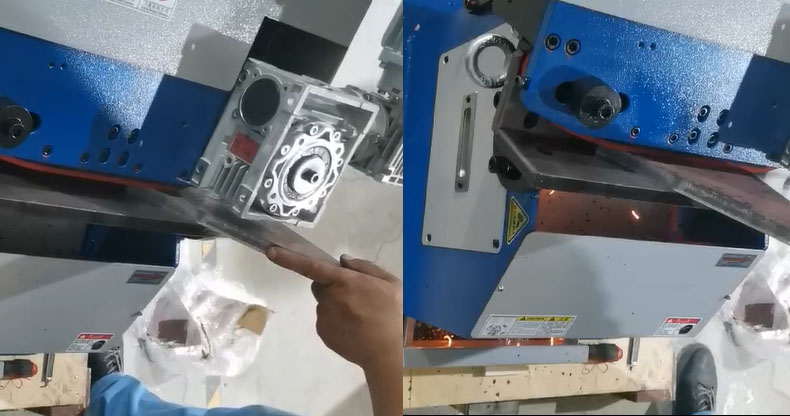

When we arrived at the site, we learned that the workpieces that the customer needed to process were all small pieces with a thickness of less than 18mm, such as triangular plates and angular plates. The workpiece for video processing is 18mm thick with 45 degree up and down bevels.

According to the customer's process requirements, we recommend that they choose the TMM-20T portable edge milling machine.

This machine is suitable for small workpiece bevels with a thickness of 3-30mm, and the bevel angle can be adjusted from 25-80.

Technical parameters of TMM-20T small plate beveling machine/automatic steel plate beveling machine:

| Power supply: AC380V 50HZ (customizable) | Total power: 1620W |

| Processing board width:>10mm | bevel angle: 30 degrees to 60 degrees (other angles can be customized) |

| Processing plate thickness: 2-30mm (customizable thickness 60mm) | Motor speed: 1450r/min |

| Maximum bevel width: 15mm | Execution standards: CE, ISO9001:2008 |

| Feed rate: 0-1600mm/min | Net weight: 135kg |

On site processing effect display:

After processing, the finished product meets the process requirements and is delivered smoothly!

For further insteresting or more information required about Edge milling machine and Edge Beveler. please consult phone/whatsapp +8618717764772

email: commercial@taole.com.cn

Post time: Jul-28-2025