A company renowned as the "China's Priority in Petroleum and Chemical Construction," has built over 300 large and medium-sized petroleum refining and chemical plants both domestically and internationally during its half-century development, achieving 18 national "priority" projects in petroleum and chemical construction. Particularly since the Ninth Five-Year Plan, the company has actively adapted to the internationalization strategy of the petroleum industry, continuously expanded its market, and undertaken a series of landmark projects, setting new national records in refining, chemical, and oil and gas storage and transportation engineering. Adhering to the operational strategy of "rooted in petroleum, serving the domestic market, and expanding overseas," the company focuses on refining and strengthening its core business while advancing technological and managerial innovation. In 2002, it obtained the Class T qualification for general contracting of petroleum and chemical construction projects, along with comprehensive professional certifications for the design, manufacturing, and installation of three categories of pressure vessels and ASME code-compliant products. Its 11 engineering branches (factories) can independently undertake the construction of petroleum and chemical facilities, as well as the design, manufacturing, and installation of large spherical tanks. Currently, the company employs 1,300 high and intermediate-level technical personnel and 251 certified project managers, leading over 50 project management teams. Its construction operations span both domestic and international markets, with an annual comprehensive capacity of 1.5 billion yuan and non-standard equipment manufacturing exceeding 20,000 tons. It holds a leading position in the petroleum and chemical construction industry.

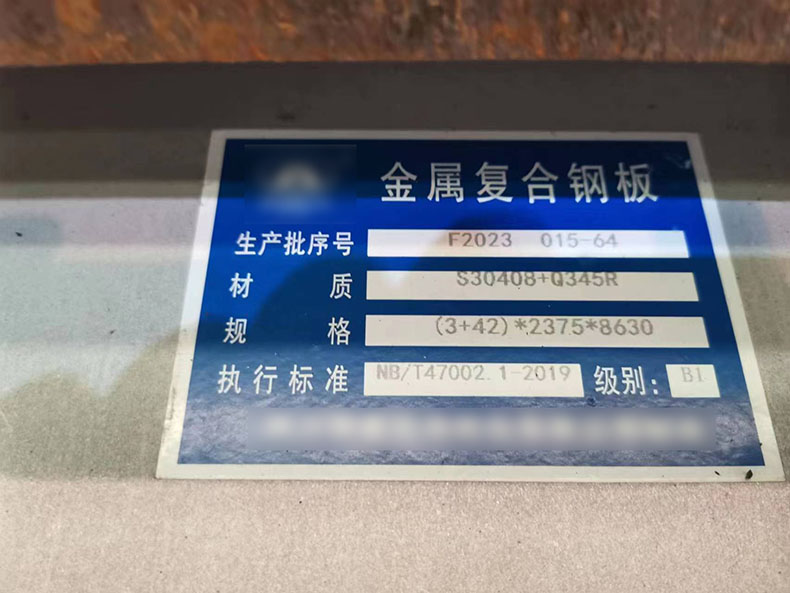

The material of the workpiece processed on site is S30408+Q345R, with a plate thickness of 45mm. The processing requirements are upper and lower V-shaped bevels, with a V-angle of 30 degrees and a blunt edge of 2mm. The surface is stripped of the composite layer, and the side edges are cleaned.

Based on the process requirements and evaluation of various product indicators, it is recommended to use Taole TMM-100L edge milling machine and TMM-80R plate beveling machine to complete the processing.

TMM-100L beveling machine for metal is mainly used for processing thick plate bevel and stepped bevel of composite plates, and is widely used for excessive bevel operations in pressure vessels and shipbuilding.

In the fields of petrochemicals, aerospace, and large-scale steel structure manufacturing.

Large single processing volume, with a slope width of up to 30mm, high efficiency, and the ability to remove composite layers, as well as U-shaped and J-shaped bevel.

Post time: Dec-08-2025