Steel plate beveling machine milling and flame beveling machine have different characteristics and application ranges in beveling processing, and the choice of which one is more cost-effective depends on specific needs and conditions.

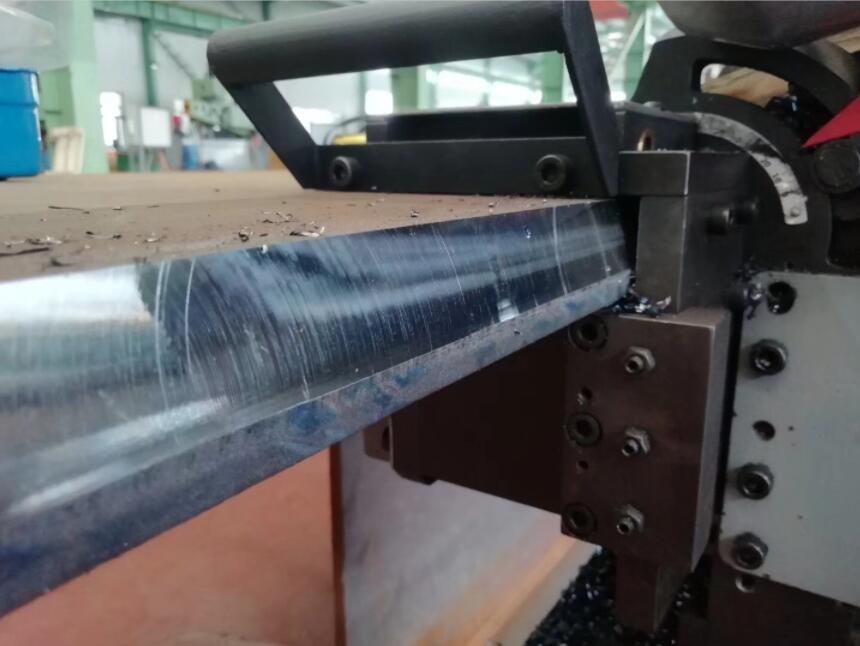

Steel plate groove milling machine usually uses mechanical force for cutting and processing, suitable for harder materials and situations with high requirements for groove quality. Relatively speaking, the price of steel plate bevel milling equipment is usually higher, but it may be more cost-effective in long-term use because it can provide high-precision and efficient processing.

The flame beveling machine processes steel plate grooves through flame combustion, suitable for thicker steel plates and conditions with relatively low requirements for groove quality. Flame beveling machines are usually cheaper, but their processing speed is slower and may require more follow-up processing.

Therefore, to choose a more cost-effective method, you need to consider the following factors:

-Material type and thickness: If you need to process harder materials or thicker steel plates, it is recommended to use a steel plate beveling machine for milling.

-Quality requirements for bevels: If you have high requirements for beveling quality, steel plate beveling machine milling is usually more suitable.

-Budget limitation: If your budget is limited, flame beveling machines may be a more economical choice, especially for low-demand beveling.

Based on the above factors, it is recommended that you choose the groove processing equipment that is suitable for you according to specific needs and budget constraints.

The cost-effectiveness of steel plate beveling machine milling and flame beveling machine depends on specific application scenarios and work requirements. Here are some evaluation factors to help you make decisions:

1. Processing materials and thickness: If you need to process harder materials or thicker steel plates, steel plate bevel milling may be more suitable because it can provide higher cutting force and processing accuracy.

2. Quality requirements for bevel: If you have extremely high requirements for bevel quality, steel plate bevel machine milling can usually provide better results. It can achieve precise and consistent groove shapes and sizes.

3. Work quantity and time requirements: Flame beveling machines are usually suitable for large-scale beveling processing, especially for thicker steel plates. It has a relatively fast processing speed and can efficiently complete work.

4. Budget constraints: Considering equipment prices and operating costs, flame beveling machines are usually more cost-effective than steel plate beveling machines for milling. It has a lower price and requires lower maintenance and tool costs.

Overall, the choice of which device offers better cost-effectiveness depends on your specific needs and budget constraints. If you have high requirements for accuracy and quality, and require greater flexibility when processing harder materials, then steel plate bevel machine milling may be a better choice. If it is necessary to handle large-scale processing tasks and the budget is relatively limited, the flame beveling machine may be a more cost-effective option.

Post time: Mar-12-2024