The pharmaceutical industry is renowned for its stringent quality standards and precise manufacturing processes. The TMM-60S plate beveling machine is one of the key pieces of equipment for enhancing efficiency and accuracy in this industry. This advanced machine has played a significant role in various machining applications, and this article will demonstrate its superior performance through detailed case studies. The TMM-60S Steel

Plate beveling machine is designed for machining a wide range of materials, making it ideal for the pharmaceutical industry. Its robust construction and sophisticated engineering enable it to mill materials of complex shapes and sizes, crucial for the production of pharmaceutical components. In a recent case study, a leading pharmaceutical company adopted the TMM-60S to optimize its production line, primarily for milling tablet molds and other critical components.

Case Introduction

A certain pharmaceutical machinery Co., Ltd. is mainly engaged in the production of pharmaceutical equipment (sterile isolator equipment), mechanical equipment (non sterile isolator equipment) and their accessories (transfer valves, sampling valves).

The problem that needs to be solved is the processing of the upper and lower bevels of the plate. It is recommended to use the TMM-60S automatic beveling machine for plate, which has a single motor and high power. It can be used for processing steel, chromium iron, fine grain steel, aluminum products, copper and various alloys.

l Characteristic:

l lReduce usage costs and alleviate labor intensity

l lCold cutting operation, with no oxidation on the bevel surface

l lThe slope surface smoothness reaches Ra3.2-6.3

l lThis product is efficient and easy to operate

Product parameters

|

Product Model |

GMMA-60S |

Processing board length |

>300mm |

|

Power Supply |

AC 380V 50HZ |

Bevel angle |

0°~60°Adjustable |

|

Total Power |

3400W |

Single Bevel Width |

0~20mm |

|

Spindle Speed |

1050r/min |

Bevel Width |

0~45mm |

|

Feed Speed |

0~1500mm/min |

Blade Diameter |

φ63mm |

|

Thickness of clamping plate |

6~60mm |

Number of blades |

6pcs |

|

Clamping plate width |

>80mm |

Workbench height |

700*760mm |

|

Gross weight |

255kg |

Package size |

800*690*1140mm |

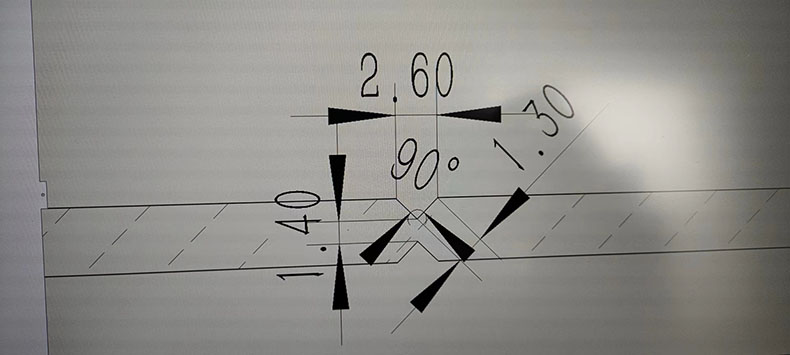

The board is made of 4mm 316 material, and the process requires a 45 degree V-shaped bevel with a 1.4mm blunt edge in the middle.

GMMA-60S beveling machine on-site testing:

GMMA-60S steel plate beveling machine processing effect display:

GMMA-60S beveling machine for plate features:

The groove is uniform, and the surface smoothness can reach 3.2-6.3Ra. Resin wheel transmission does not cause damage to the surface of the base material.

Post time: Jan-13-2026