In the ever-evolving machining industry, the integration of advanced technologies has become paramount for enhancing productivity and precision. A notable example is the TMM-80A steel plate beveling machine, which has revolutionized the way steel plates are processed, particularly in conjunction with flat plate beveling machines.

The business scope of a certain mechanical equipment limited company includes the manufacturing, processing, and sales of general machinery and accessories, specialized equipment, electrical machinery and equipment; Processing of hardware and non-standard metal structural components.

The processed workpiece materials are mostly carbon steel plates and alloy plates, with a thickness of (6mm -30mm), mainly processing 45 degree welding bevels.

Recommend using TMM-80A Plate beveling machine

Product parameters

|

Product Model |

TMM-80A |

Processing board length |

>300mm |

|

Power Supply |

AC 380V 50HZ |

Bevel angle |

0~60°Adjustable |

|

Total power |

4800W |

Single Bevel width |

15~20mm |

|

Spindle speed |

750~1050r/min |

Bevel width |

0~70mm |

|

Feed Speed |

0~1500mm/min |

Blade diameter |

φ80mm |

|

Thickness of clamping plate |

6~80mm |

Number of blades |

6pcs |

|

Clamping plate width |

>80mm |

Workbench height |

700*760mm |

|

Gross weight |

280kg |

Package size |

800*690*1140mm |

Characteristics of TMM-80A beveling machine for metal

1. Reduce usage costs and alleviate labor intensity

2. Cold cutting operation, no oxidation on the groove surface

3. The slope surface smoothness reaches Ra3.2-6.3

4. This product has high efficiency and simple operation

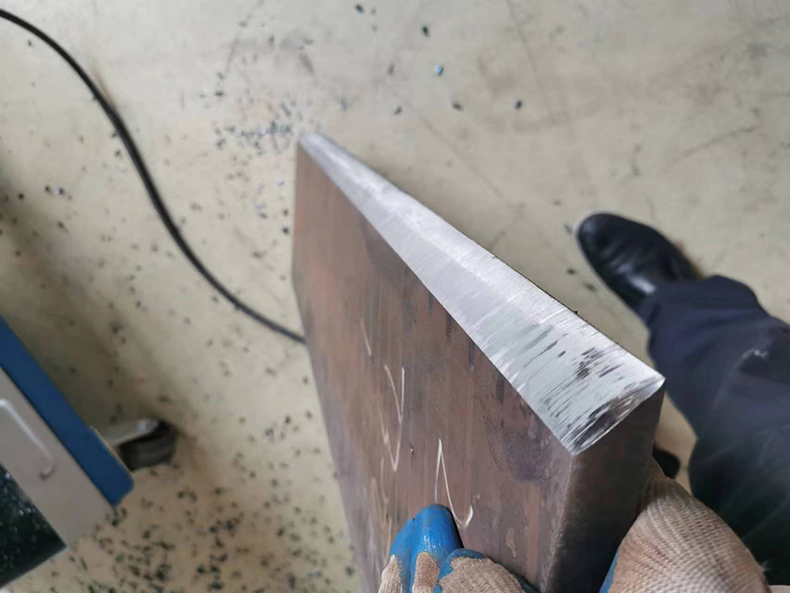

This equipment can complete the processing of the vast majority of welding bevels. The equipment has a self balancing floating function, which can cope with the effects of uneven terrain and slight deformation of workpieces. The dual frequency conversion can adjust the speed, corresponding to different milling speeds and speeds for carbon steel, stainless steel, composite materials, etc. On site bevel effect display.

Display of semi-finished products after bevel rolling and welding:

For further insteresting or more information required about Edge milling machine and Edge Beveler. please consult phone/whatsapp +8618717764772

email: commercial@taole.com.cn

Post time: Nov-28-2025