Case Introduction

Located in a certain economic development zone of Suzhou, a mechanical Co., Ltd. is a manufacturing enterprise specializing in providing structural component services for world-class construction machinery (such as excavators, loaders, etc.) and industrial machinery (like forklifts, cranes, etc.) manufacturers (e.g., Sandvik, Konecranes, Linde, Haulotte, VOLVO, etc.).

The issue to be addressed is the simultaneous machining of upper and lower bevels on the plate. It is recommended to use the TMM-100K steel plate beveling machine

TMM-100K edge milling machine, dual electromechanical high-power, spindle and walking speed adjustable by dual frequency conversion, can be used for processing steel, chromium iron, fine grain steel, aluminum products, copper and various alloys. Mainly used for groove processing operations in industries such as construction machinery, steel structures, pressure vessels, ships, aerospace, etc.

| Product Model | TMM-100K | Total Power | 6480W |

| Power Supply | AC 380V 50HZ | Processing board length | >400mm |

| Cutting Power | 2*3000W | Single Bevel width | 0~20mm |

| Walking Motor | 2*18W | Width of uphill slope | 0°~90°Adjustable |

| Spindle Speed | 500~1050r/min | Downhill angle | 0°~45°Adiustable |

| Feed Rate | 0~1500mm/min | Width of uphill slope | 0~60mm |

| Add plate thickness | 6~100mm | Downhill width | 0~45mm |

| Add board width | >100mm (non machined edge) | Workbench height | 810*870mm |

| Blade diameter | 2*ф 63mm | Walking area | 800*800mm |

| Number of blades | 2*6pcs | Package dimensions | 950*1180*1430mm |

| Net weight | 430kg | Gross weight | 460kg |

The board is Q355 with a thickness of 22mm, and the process requires a 45 degree bevel with a 2mm blunt edge in the middle.

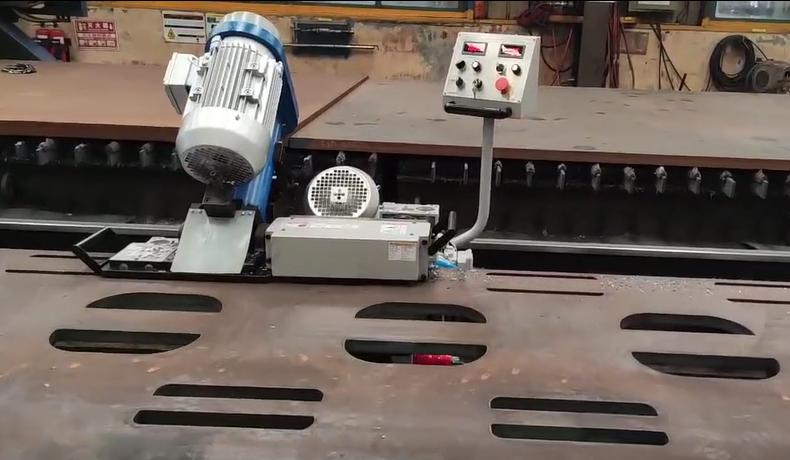

Front processing display:

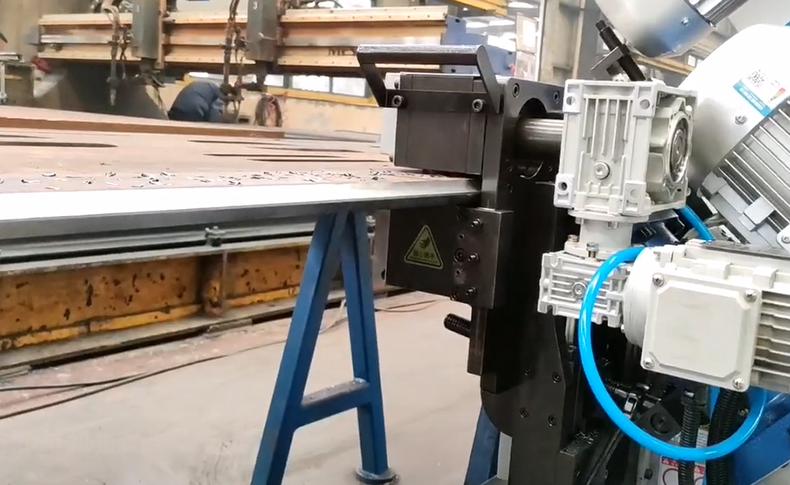

Side processing display:

The processed slope effect fully meets the process requirements.

The use of TMM-100K beveling machine in the mechanical processing industry has improved both efficiency and safety, mainly reflected in the following aspects:

1. Simultaneous processing of upper and lower grooves increases efficiency by nearly twice.

2. The device comes with a floating self balancing function, effectively solving the problem of uneven grooves caused by uneven ground and workpiece deformation.

3. There is no need to flip over the downhill slope, which effectively ensures the safety of workers.

4. The equipment design is compact, with a small volume, and the site space can be maximally utilized.

Post time: Nov-25-2025