In the modern shipbuilding industry, precise machining technology is crucial for ensuring ship quality and production efficiency. The TMM-80R beveling machine, as a high-performance steel plate beveling machine, has become an essential tool in large shipyards due to its superior machining capabilities and flexible application range. This article will explore application cases of the TMM-80R plate beveling machine in large shipyards, demonstrating how it improves production efficiency and machining accuracy.

Case Introduction

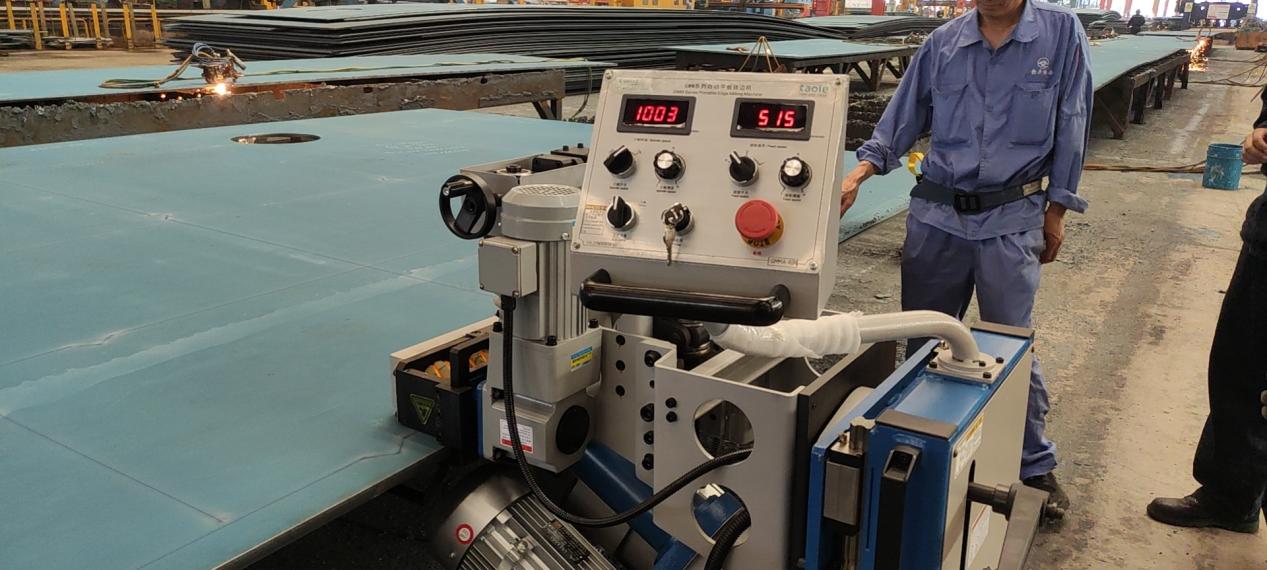

TMM-80R Application Case Study of Milling Machine in Large Shipyard

A large shipyard in Jiangsu province

Main business:

Design, manufacture, research, installation, maintenance, and sales of self-produced products for metal vessels, marine engineering specialized equipment, marine supporting equipment, steel structures, offshore oil and gas drilling and production equipment; Ship retrofitting; Research and design of drilling and production automation systems, drilling technology services, etc.

Characteristics

l lReduce usage costs,

l lReduce labor intensity in cold cutting operations,

l lThe surface of the bevel is free of oxidation, and the smoothness of the slope surface reaches Ra3.2-6.3

l lThis product is efficient and easy to operate

Product Parameters

| Product model | GMMA-80R | Processing plate length | >300mm |

| Power supply | AC 380V 50HZ | Bevel angle | 0°~±60°Adjustable |

| Total power | 4800W | Single bevel width | 0~20mm |

| Spindle speed | 750~1050r/min | Bevel width | 0~70mm |

| Feed rate | 0~1500mm/min | Blade diameter | φ80mm |

| Thickness of clamping plate | 6~80mm | Number of blades | pcs |

| Clamping plate width | >100mm | Workbench height | 700*760mm |

| Gross weight | 385kg | Package dimensions | 1200*750*1300mm |

A bevel with a 30-degree uphill angle and a 10-degree downhill angle, leaving a 1mm blunt edge on the center seam, which is also completed in one pass for both the uphill and downhill sides.

Another type is the single down-facing bevel, which requires only one machine. On-site, a 20mm-thick carbon steel plate is beveled upward to a depth of 12mm with an 8mm blunt edge and a 30-degree angle. The equipment can complete the beveling in a single pass, fully meeting the client's requirement of not needing to flip the plate on-site. The client's production department head expressed great satisfaction and looks forward to further collaboration.

For further insteresting or more information required about Edge milling machine and Edge Beveler. please consult phone/whatsapp +8618717764772

email: commercial@taole.com.cn

Post time: Jan-14-2026