GCM-R3T Rounding machine

Short Description:

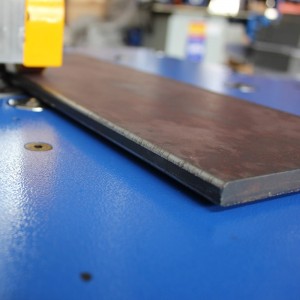

GCM-R3T Metal Edge Rounding Machine for Radius R2, R3, C3, supply a quick and easy radius edge beveling solution designed for paint ready edge preparation of steel plates and profiles. Designed specifically for the steel fabricator as a solution which demands a soft or radius edge applying to all steel sections before painting, to prevent rust build up on sharp edges. This quick simple to use system with a single head and milling inserts, creates a perfect radius in just one pass, saving time and money grinding methods.a

Products Description

TCM Series Edge Rounding Machine is kind of equipment for steel plate edge rounding /chamfering/de-burring. It is functional or option for single edge rounding or double sided rounding. Mostly for Radius R2, R3,C2,C3.This Machine are widely used for carbon steel, stainless steel, aluminum steel ,alloy steel etc.Mainly applicated for Shipyard, construture industry for painting preparation to achieve a durable corrosion resistance.

Edge rounding equipment from Taole Machine removes sharp metal edges, increasing worker and equipment safety as well as paint and coating adhesion.

Optional models as per sheet metal specifications shape & Size and metal job attribute.

Main Advantages

1. Stationary Machine Suitable for bulk processing, Mobile type and pass-type for large plate with high efficiency by multiple spindles.

2. Ballast Tank PSPC Standard.

3. Unique machine design request small work space only.

4. Cold cutting to avoid any Indentation and oxide layer . Using market standard milling head and carbide inserts

5. Radiu available for R2,R3, C2,C3 or more possible R2-R5

6. Wide working range, easy to adjust for edge chamfering

7. High working speed which estimated to be 2-4 m/min

Parameter Comparison Table

| Models | TCM-SR3-S |

| Power Suppy | AC 380V 50HZ |

| Total Power | 790W& 0.5-0.8 Mpa |

| Spindle Speed | 2800r/min |

| Feed Speed | 0~6000mm/min |

| Clamp Thickness | 6~40mm |

| Clamp Width | ≥800mm |

| Clamp Length | ≥300mm |

| Bevel Width | R2/R3 |

| Cutter Diameter | 1 * Dia 60mm |

| Inserts QTY | 1 *3 pcs |

| Worktable Height | 775-800mm |

| Worktable Size | 800*900mm |

Process Performance