The TMM-100L plate beveling machine has become a key tool in the pressure vessel industry, demonstrating its versatility and efficiency in a variety of applications. Designed specifically to meet the demanding requirements of plate milling, this advanced milling machine is the ideal choice for pressure vessel manufacturers.

One of the primary applications of the TMM-100L beveling machine is for the pretreatment of steel plates before welding. In the pressure vessel industry, precision is paramount, as any defect can lead to catastrophic failure. The GMMA-100L ensures that the steel plate is milled to precise dimensions, resulting in a smooth, uniform surface and improved weld quality. This capability not only enhances the structural integrity of the vessel but also reduces the probability of post-weld defects.

Another important application is the machining of complex geometries required for pressure vessel components. The GMMA-100L is equipped with advanced milling technology, enabling the high-precision machining of complex shapes. This is particularly advantageous for manufacturers who need to customize pressure vessels to meet specific industry requirements, such as those used in the oil and gas, chemical, and power generation industries.

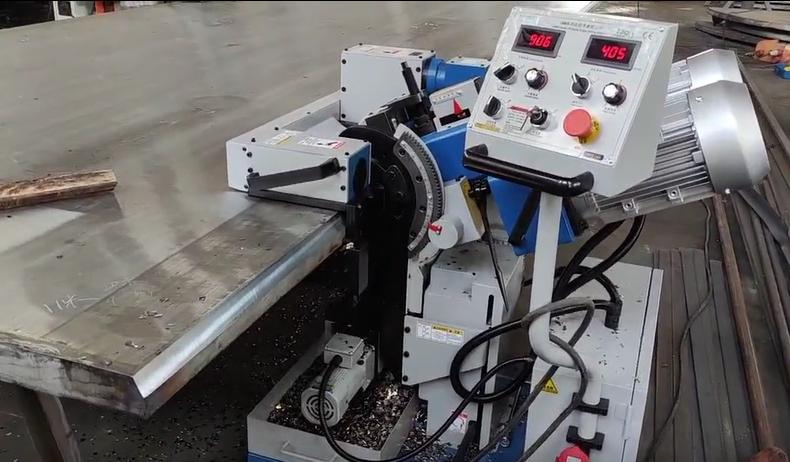

Case Introduction

A large pressure vessel boiler factory needs to process 40mm thick stainless steel plates.

In response to the customer's demand, based on industry experience, we recommend that the customer choose the Taole TMM-100L steel plate beveling machine.

Product Parameter

|

Power supply voltage |

AC380V 50HZ |

|

Total power |

6520W |

|

Cutting energy consumption |

6400W |

|

Spindle speed |

500~1050r/min |

|

Feed rate |

0-1500mm/min (varies according to material and feed depth) |

|

Clamping plate thickness |

8-100mm |

|

Clamping plate width |

≥ 100mm (non machined edge) |

|

Processing board length |

> 300mm |

|

Bevel angle |

0 °~90 ° Adjustable |

|

Single bevel width |

0-30mm (depending on bevel angle and material changes) |

|

Width of bevel |

0-100mm (varies according to the angle of the bevel) |

|

Cutter Head diameter |

100mm |

|

Blade quantity |

7/9pcs |

|

Weight |

440kg |

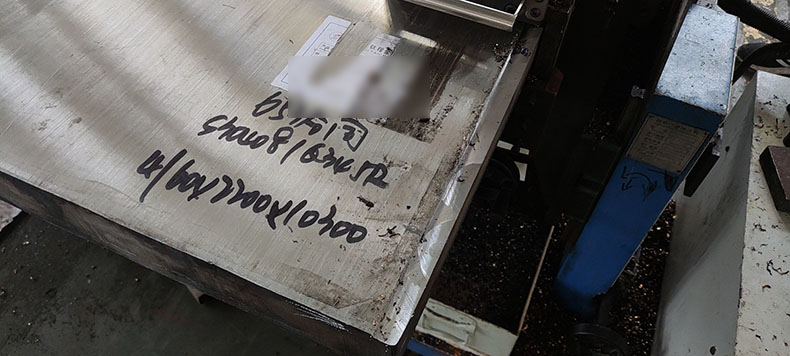

On site, there are large plates with long bevels, 40mm thick stainless steel plates, half made, with an angle of 30 degrees and a 20mm deep bevels.

Set the speed to 400mm/minute and complete it with one cut. The process requires an X-shaped bevel. After flipping the board over, take another cut and complete it smoothly.

To meet the on-site process requirements and standards, due to the large processing volume, 4 TMM-100L edge milling machines are required for simultaneous processing. The customer has placed an additional equipment order on site and signed a long-term cooperation plan!

Post time: Jan-05-2026