Case Introduction

In the pharmaceutical industry, precision and efficiency are paramount, especially in the production of active pharmaceutical ingredients (APIs) and other critical components.

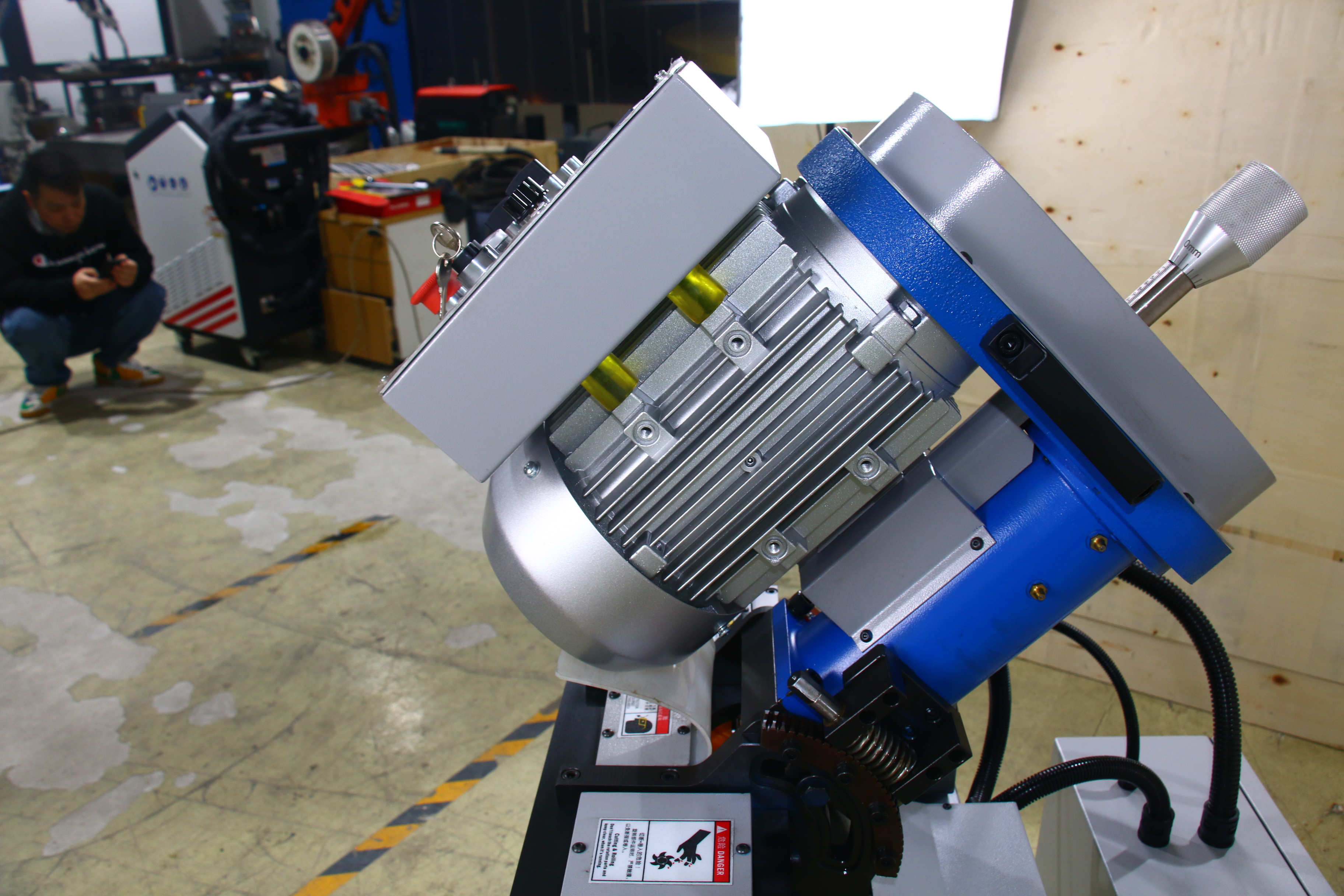

The TMM-60S beveling machine surface grinder is a highly anticipated innovative solution that demonstrates significant advantages in surface grinding operations. The TMM-60S grinding mill is designed to process a variety of materials, including metals and polymers, making it suitable for a wide range of pharmaceutical applications. A recent case study highlights its application in a leading pharmaceutical plant with extremely high requirements for high-quality grinding processes to ensure consistent and reliable product quality.

A certain pharmaceutical machinery Co., Ltd. is mainly engaged in the production of pharmaceutical equipment (sterile isolator equipment), mechanical equipment (non sterile isolator equipment) and their accessories (transfer valves, sampling valves).

The problem that needs to be solved is the processing of the upper and lower bevels of the plate. It is recommended to use the TMM-60S automatic edge milling machine, which has a single motor and high power. It can be used for processing steel, chromium iron, fine grain steel, aluminum products, copper and various alloys.

Characteristic:

l Reduce usage costs and alleviate labor intensity

l Cold cutting operation, with no oxidation on the bevel surface

l The slope surface smoothness reaches Ra3.2-6.3

l This product is efficient and easy to operate

Product parameters

|

Product Model |

GMMA-60S |

Processing board length |

>300mm |

|

Power Supply |

AC 380V 50HZ |

Bevel angle |

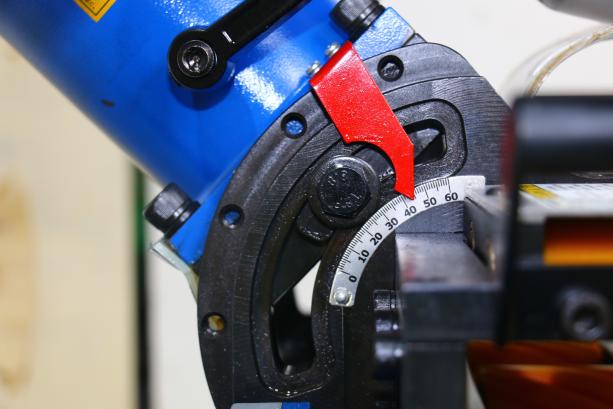

0°~60°Adjustable |

|

Total Power |

3400W |

Single Bevel Width |

0~20mm |

|

Spindle Speed |

1050r/min |

Bevel Width |

0~45mm |

|

Feed Speed |

0~1500mm/min |

Blade Diameter |

φ63mm |

|

Thickness of clamping plate |

6~60mm |

Number of blades |

6pcs |

|

Clamping plate width |

>80mm |

Workbench height |

700*760mm |

|

Gross weight |

255kg |

Package size |

800*690*1140mm |

Product details

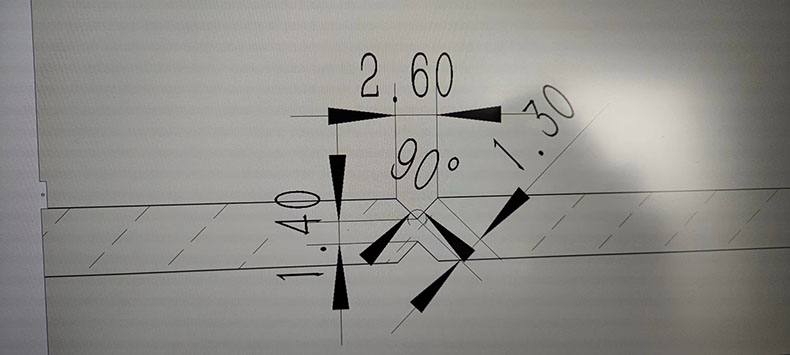

The board is made of 4mm 316 material, and the process requires a 45 degree V-shaped bevel with a 1.4mm blunt edge in the middle.

TMM-60S beveling machine for metal on-site testing:

TMM-60S edge milling machine processing effect display:

TMM-60S plate beveling machine features:

The bevel is uniform, and the surface smoothness can reach 3.2-6.3Ra.

Resin wheel transmission does not cause damage to the surface of the base material.

Post time: Dec-29-2025