Orbital Pipe Cutting and Beveling Machine TOP-230

Short Description:

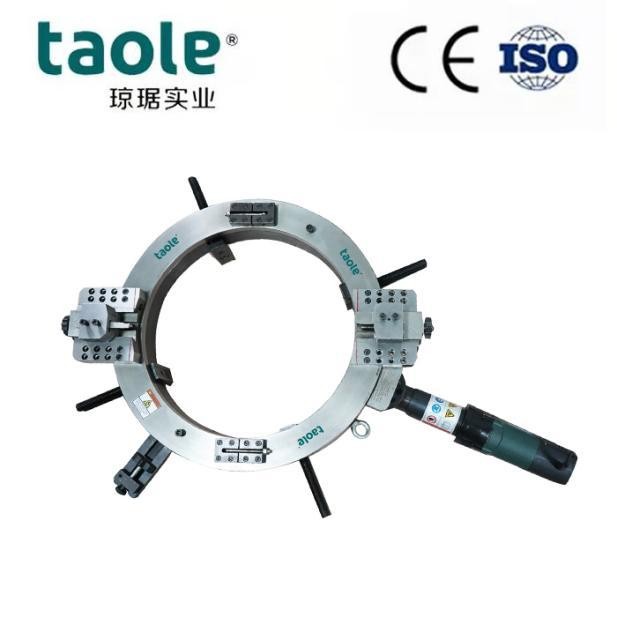

OCE/OCP/OCH models of pipe cutting and beveling machine is ideal options for all types of pipe cold cutting, beveling and end preparation. The split frame design allows the machine to split in half at the frame and mount around the OD (Outer beveling) of the in-line pipe or fittings for strong, stable clamping. The equipment performs precision in-line cut or simultaneous process on cold cutting and beveling, single point, counterbore and flange facing operations, as well as weld end preparation on open ended pipes /tubes.

Description

The series machine is ideal for all types of pipes cutting, beveling and end preparation. The split frame design allows the machine to split in half at the frame and mount around the OD of the in-line pipe or fittings for strong, stable clamping. The equipment performs precision in-line cut or simultaneous cut/bevel, single point, counterbore and flange facing operations, as well as weld end preparation on open ended pipe, Ranging from 3/4” to 48 inches O.D.(DN20-1400), on most wall thicknesses and material.

Main features

1.Cold cutting and beveling improves safety

2. Cutting and beveling simultaneously

3. Split frame, easy mounted on pipeline

4. Fast, Precision, On-site beveling

5. Minimal Axial and Radial Clearance

6. Light weight and compact design Easy set-up & Operation

7. Electric or Pneumatic or Hydraulic driven

8. Machining Heavy-wall pipe from 3/8’’ up to 96’’

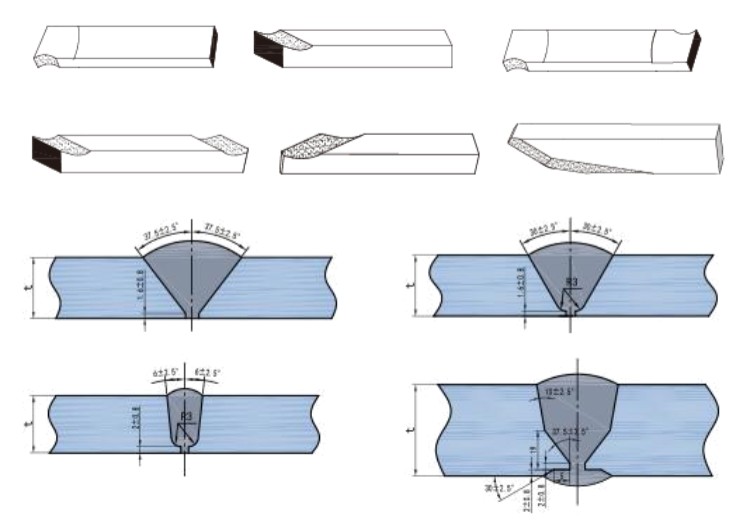

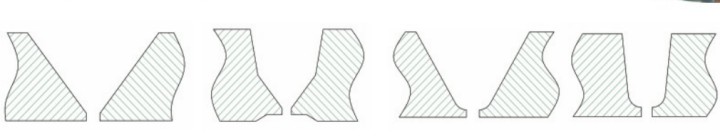

Tool Bits &Typical Buttwelding Joint

Product Specifications

Power Supply: 0.6-1.0 @1500-2000L/min

| Model NO. | Working Range | Wall Thickness | Rotation Speed | Air Pressure | Air Consumption | |

| OCP-89 | φ 25-89 | 3/4‘’-3‘’ | ≤35mm | 50 r/min | 0.6~1.0MPa | 1500 L/min |

| OCP-159 | φ50-159 | 2‘’-5‘’ | ≤35mm | 21 r/min | 0.6~1.0MPa | 1500 L/min |

| OCP-168 | φ50-168 | 2‘’-6‘’ | ≤35mm | 21 r/min | 0.6~1.0MPa | 1500 L/min |

| OCP-230 | φ80-230 | 3‘’-8‘’ | ≤35mm | 20 r/min | 0.6~1.0MPa | 1500 L/min |

| OCP-275 | φ125-275 | 5‘’-10‘’ | ≤35mm | 20 r/min | 0.6~1.0MPa | 1500 L/min |

| OCP-305 | φ150-305 | 6‘’-10‘’ | ≤35mm | 18 r/min | 0.6~1.0MPa | 1500 L/min |

| OCP-325 | φ168-325 | 6‘’-12‘’ | ≤35mm | 16 r/min | 0.6~1.0MPa | 1500 L/min |

| OCP-377 | φ219-377 | 8‘’-14‘’ | ≤35mm | 13 r/min | 0.6~1.0MPa | 1500 L/min |

| OCP-426 | φ273-426 | 10‘’-16‘’ | ≤35mm | 12 r/min | 0.6~1.0MPa | 1800 L/min |

| OCP-457 | φ300-457 | 12‘’-18‘’ | ≤35mm | 12 r/min | 0.6~1.0MPa | 1800 L/min |

| OCP-508 | φ355-508 | 14‘’-20‘’ | ≤35mm | 12 r/min | 0.6~1.0MPa | 1800 L/min |

| OCP-560 | φ400-560 | 16‘’-22‘’ | ≤35mm | 12 r/min | 0.6~1.0MPa | 1800 L/min |

| OCP-610 | φ457-610 | 18‘’-24‘’ | ≤35mm | 11 r/min | 0.6~1.0MPa | 1800 L/min |

| OCP-630 | φ480-630 | 20‘’-24‘’ | ≤35mm | 11 r/min | 0.6~1.0MPa | 1800 L/min |

| OCP-660 | φ508-660 | 20‘’-26‘’ | ≤35mm | 11 r/min | 0.6~1.0MPa | 1800 L/min |

| OCP-715 | φ560-715 | 22‘’-28‘’ | ≤35mm | 11 r/min | 0.6~1.0MPa | 1800 L/min |

| OCP-762 | φ600-762 | 24‘’-30‘’ | ≤35mm | 11 r/min | 0.6~1.0MPa | 2000 L/min |

| OCP-830 | φ660-813 | 26‘’-32‘’ | ≤35mm | 10 r/min | 0.6~1.0MPa | 2000 L/min |

| OCP-914 | φ762-914 | 30‘’-36‘’ | ≤35mm | 10 r/min | 0.6~1.0MPa | 2000 L/min |

| OCP-1066 | φ914-1066 | 36‘’-42‘’ | ≤35mm | 9 r/min | 0.6~1.0MPa | 2000 L/min |

| OCP-1230 | φ1066-1230 | 42‘’-48‘’ | ≤35mm | 8 r/min | 0.6~1.0MPa | 2000 L/min |

|

|

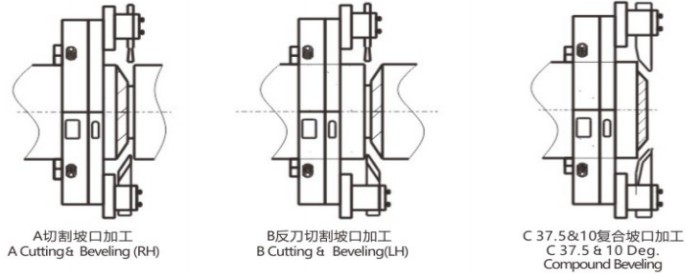

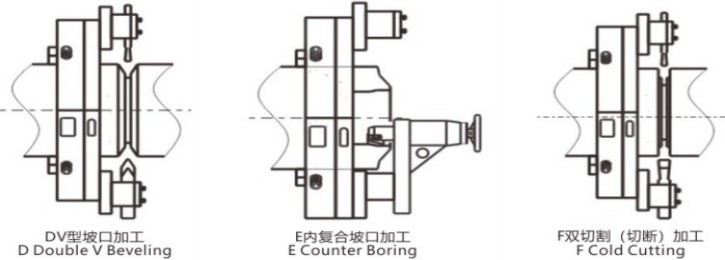

Machine Design and Power Drive Option

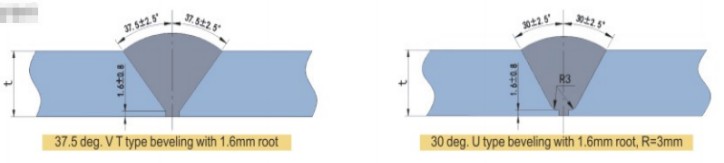

Schematic View And Typital of Butt welding

|

|

Example diagram of bevel type Example diagram of bevel type |

|

|

|

|

|

On site cases

|

|

Machine Package

|

|

FAQ

Q1: What is the power supply of the machine?

A: Optional Power Supply at 220V/380/415V 50Hz. Customized power /motor/logo/Color available for OEM service.

Q2: Why comes multi models and how should I Choose and understand?

A: We have different models based on customer’s requirements. Mainly different on power, Cutter head, bevel angel, or special bevel joint required. Please send a inquiry and share your requirements ( Metal Sheet specification width * length * thickness, required bevel joint and angel). We will present you with best solution based on general conclusion.

Q3: What is the delivery time?

A: Standard machines are stock available or spare parts available which able to be ready in 3-7 days. If you have special requirements or customized service. Normally takes 10-20 days after order confirm.

Q4: What is the warranty period and after sales service?

A: We provide 1 year warranty for machine except wearing parts or consumables. Optional for Video Guide, Online Service or local Service by third party. All spare parts available in both Shanghai and Kun Shan Warehouse in China for fast moving and shipping.

Q5: What is your payment Teams?

A: We welcome and try multi payment terms depends on order value and necessary. Will suggest 100% payment against fast shipment. Deposit and balance % against cycle orders.

Q6: How do you pack it?

A: Small machine tools packed in tool box and carton boxes for safety shipments by courier express. Heavy machines weight higher than 20 kgs packed in wooden cases pallet against safety shipment by Air or Sea. Will suggest bulk shipments by sea considering machine sizes and weight.

Q7: Are you Manufacture and what is your products range?

A: Yes. We are manufacture for beveling machine since 2000.Welcome to visit our factory in Kun shan City. We concentrating on metal steel beveling machine for both plate and pipes against welding preparation. Products including Plate Beveler, Edge Milling Machine, Pipe beveling, pipe cutting beveling machine, Edge rounding /Chamfering, Slag removal with standard and customized solutions.

Welcome to contact us anytime for any inquiry or more informations.

1-300x300.jpg)

1-300x300.jpg)

1-300x274.jpg)

-300x300.jpg)

1-300x300.jpg)