Shipbuilding is a complex and demanding industry, requiring precision engineering and high-quality materials. One of the key tools revolutionizing this industry is the plate beveling machine. This advanced machinery plays a vital role in the manufacture and assembly of various ship components, ensuring they meet stringent safety and performance standards. Plate edge beveling machine are designed for high-precision machining of large steel plates. In shipbuilding, these machines are primarily used to create the complex shapes and contours required for hulls, decks, and other structural components of ships. The ability to mill steel plates to precise dimensions enables shipbuilders to achieve a perfect fit during assembly, which is crucial for maintaining the integrity and stability of a vessel.

This time we are introducing a large shipbuilding group in the north that needs to process a batch of special plates.

The requirement is to make a 45 ° bevel on a 25mm thick steel plate, leaving a 2mm blunt edge at the bottom for one cut molding.

According to the customer's requirements, our technical personnel recommend using the Taole TMM-100L automatic steel plate edge milling machine. Mainly used for processing thick plate bevels and stepped bevels of composite plates, it is widely used in excessive bevel operations in pressure vessels and shipbuilding, and plays a significant role in fields such as petrochemicals, aerospace, and large-scale steel structure manufacturing.

The single processing volume is large, and the slope width can reach 30mm, with high efficiency. It can also achieve the removal of composite layers and U-shaped and J-shaped bevels.

Product Parameter

|

Power supply voltage |

AC380V 50HZ |

|

Total power |

6520W |

|

Cutting energy consumption |

6400W |

|

Spindle speed |

500~1050r/min |

|

Feed rate |

0-1500mm/min (varies according to material and feed depth) |

|

Clamping plate thickness |

8-100mm |

|

Clamping plate width |

≥ 100mm (non machined edge) |

|

Processing board length |

> 300mm |

|

Bevel angle |

0 °~90 ° Adjustable |

|

Single bevel width |

0-30mm (depending on bevel angle and material changes) |

|

Width of bevel |

0-100mm (varies according to the angle of the bevel) |

|

Cutter Head diameter |

100mm |

|

Blade quantity |

7/9pcs |

|

Weight |

440kg |

This sample test has indeed brought great challenges to our machine, which is basically a machining operation with a completely full blade. We have adjusted the parameters several times and fully met the process requirements.

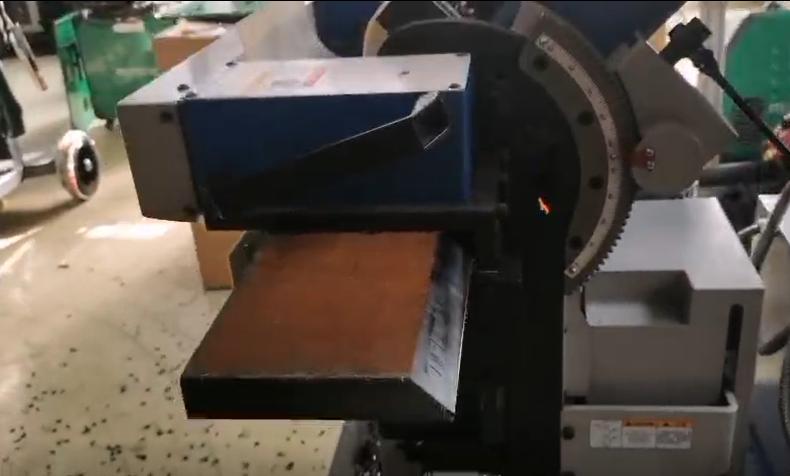

Testing process demonstration:

Post processing effect display:

The customer expressed great satisfaction and finalized the contract on the spot. We are also very fortunate because the customer's recognition is the highest honor for us, and dedicating to the industry is our belief and dream that we have always upheld.

Post time: Aug-18-2025